COMPACTORS

VIBRATORS

|

|

||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

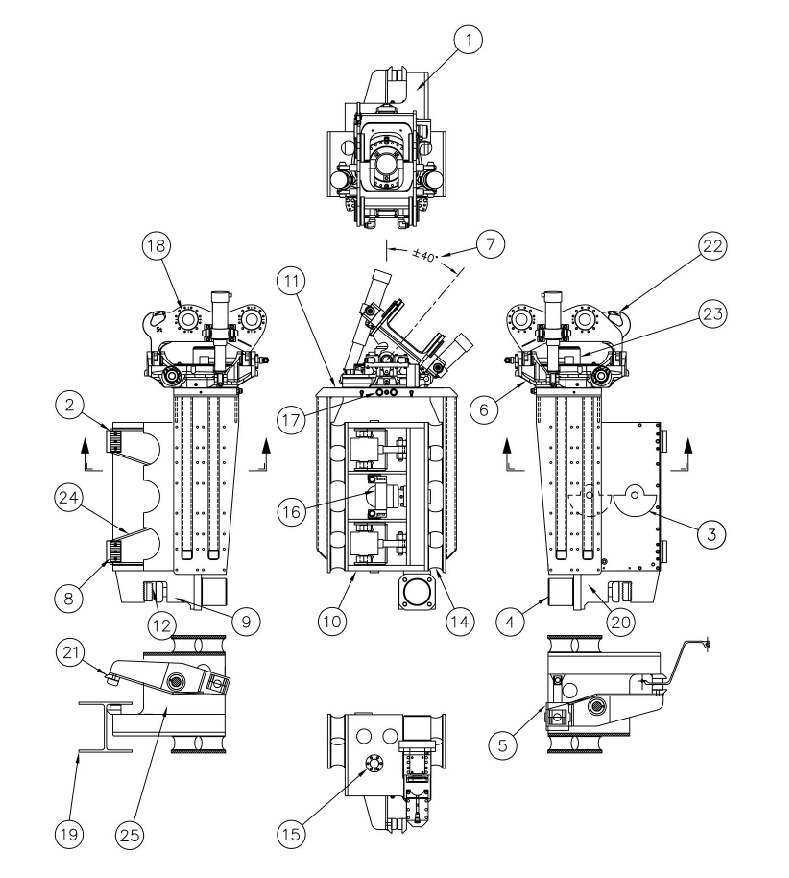

MODEL 20 E VIBRATORY DRIVER/EXTRACTOR

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||

PLEASE VISIT http://www.apevibro.com/ TODAY TO GET MORE INFO ABOUT THE COMPLETE APE LINE OF VIBRATORS |

|||||||||||||||||||||||||||||||||||||

RoboVibe

- The RoboVibe™ eccentrics are located within the fixed side grip arm. Centerline of dynamic force is much closer to the gripping jaws, reducing off center force input to pile.

- Vertical distance between side grip jaws is increased to better resists off-center force

- RoboVibe eccentric moment is 22% greater than competitive units, producing significantly larger driving amplitude.

- Each clamp has an individual actuating cylinder. No poorly guided, trouble prone, dual purpose cylinders as in competitiveunits

- Side grip cylinders are directly mounted to arms and are hydraulically synchronized.

- Proven tilt and rotate mechanism is designed for digging duty, and has sealed lubrication for bearings and worm gear. Cast housing and integral rotation motor maintain perfect alignment for worm gear and massive rotation bearing. Dual tilt cylinders are telescopic, providing lower profile and equal left and right tilt torque

- The RoboVibe +/- 40 deg tilt is 33% more than the competition, allowing additional reach when loading or unloading piles.

- Rectangular clamp jaws on side grips provide more clamping area than round jaws.

- Bottom clamp uses precision-guided slider per accepted vibratory hammer practice. Clamp cylinder is directly aligned with thefixed jaw—no offset.

- Most components contained within welded steel frame for protection and exceptional strength.

- No solenoid valves or wiring mounted on RoboVibe. Valves and wiring are remotely mounted on excavator boom to avoid vibration damage.

- Both the side grip and the bottom clamp jaws are identical to minimize inventory. Additionally, all RoboVibe jaws have the J&M exclusive “Kryponite” coating for exceptional wear life.

- Two eccentrics are horizontally stacked to minimize distance between driving force and pile center.

- Commonly available elastomers isolate vibration from excavator. Extra elastomer mounting positions are provided so springrate may be optimized for tough pile extraction applications.

- Lockable adjusting nuts eliminate clearance in side grip arms to reduce vibration wear, and insure long life.

- Commercial, high pressure gear motor is interchangeable to exactly match excavator hydraulic flow to RoboVibe. No flow controls or restrictions to cause damaging heat buildup in excavator hydraulic system

- Gun-drilled hydraulic distribution manifold is integral to suspension yoke to minimize plumbing, and perfectly align hydraulic swivel.

- Replaceable offset bushings at the excavator connection allow pin diameter and center distance changes to accommodatevarious brands and sizes of excavators.

- Minimum width, fixed side clamp arm allows driving of H-piles as small as 10”.

- Bottom clamp slider is chrome plated and greaseable via protected fitting.

- Lips on side grip arms allow “nested” sheet piles to be split for lifting access.

- Integral sling hook, with safety latch, facilitates lofting piles and other lifting.

- Large bore hydraulic swivel provides 360 deg continuous rotation, with minimum flow restriction.

- Wide, T-1 steel side grip arms provide exceptional rigidity to transmit vibratory output force.

- All hydraulic cylinders are designed for vibratory duty.

ROBOVIBE™ SPECIFICATIONS

|

Specifications |

26Ton |

||

|---|---|---|---|

| Weight: kg (lb) |

2,086 (4,600) |

||

|

Eccentric Moment: kgm (in-lb) |

5.59 (485) |

||

|

Frequency in cycles per minute: |

1,950 |

||

|

Dynamic Force: m Ton (USt) |

23.6 (26) |

||

|

Amplitude-free hanging: mm (in) |

8.74 (.344) |

||

|

Max Flow: lpm (gpm) |

151 (40) |

||

|

Maximum Pressure bar (psi) |

241 (3,500) |

||

|

Minimum Excavator m Ton (USt) |

20 (23) |

||

DOWN LOAD APE ROBOVIBE BROCHURE CLICK HERE OR PLEASE VISIT http://www.apevibro.com/ TODAY TO GET MORE INFO ABOUT THE COMPLETE APE LINE OF VIBRATORS

![quickattacha[1] quickattacha[1]](https://breakersdrillsamerica.com/images/quickattacha_1_.jpg)

![CompactorPhoto2[1] CompactorPhoto2[1]](https://breakersdrillsamerica.com/images/CompactorPhoto2_1_.jpg)