Main Features

- Low vibration which reduces fatigue.

- Maximum cutting performance and minimum service

- Low-maintenance

- Underwater operation

- High torque hydaulic motor

- Robust housing design

- Lubrication free slide ring seal system.

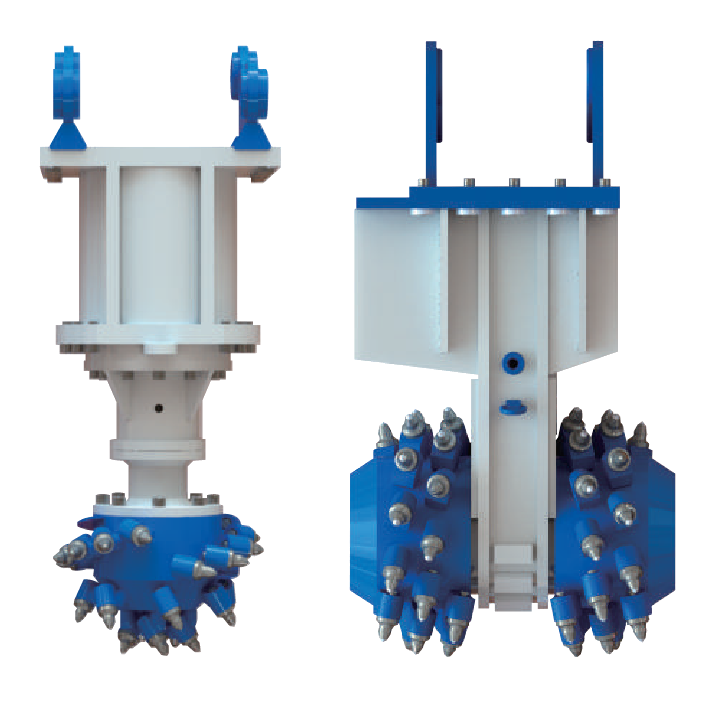

Rock Grinders use robust spur hears driven by high torque motors.

The picks on the twin drums will penetrate and remote materials through a combination of crushing and cutting action. The optimum number of pick and pick arrangement ensure a maximum cutting performance, minimum vibration and quiet operation.

Rock Grinders For Tough Applications

1. Trench / Pipeline Construction

Rock grinders produce smooth trench wall with straight parallel sides. Threnches can be excavated accuratley to the size required. The grinded materials can be re-used as back fill without additional crushing

2. Trunneling

Rock grinders are commonly used for scaling operation in tunnel construction after drilling and blasting. Profiling work is also common work in tunnel construction after blasting and before installation of ground support such as screen and bolts or shotcreating

3. Foundation Work

Rock grinders ensure safe cut under existing infrastructure such as services pipes and ventilation. Deep excavation for underground work, site preparation and leveling work can be done by this tool.

4. Demolition / Building renovation with low vibration

Rock grinders are used in urban demolition site where extremally low noise and vibration are required. They can be also used for rehabilitation of sensitive concrete structure such as foundations and bridges

5. Quarrying and Excavation

Rock grinders are an ideal tool for gypsum and limestone mining, excavation soil, soft rock, asphalt and concrete. Its combination of cutting force and precision ensure a high performance and productivity in those job sites.

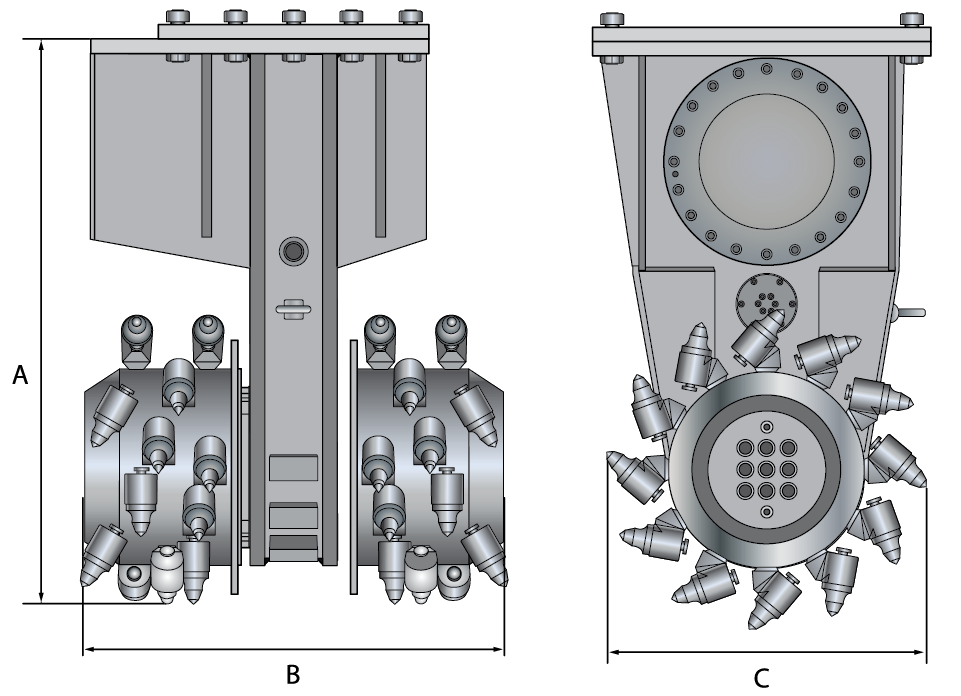

RG Twin Head Rock Grinder

| Standard Specification |

| Technical Data |

Unit |

RG05 |

RG10 |

RG15 |

RG30 |

RG40 |

RG50 |

| Carrier weight class |

TON |

3 - 7 |

7 - 15 |

12 - 18 |

20 - 33 |

25 - 40 |

35 - 50 |

| Service Weight |

KG |

390 |

420 |

800 |

1,750 |

1,850 |

2,350 |

| Oil Flow Rate |

L/MIN |

49 - 90 |

75 - 124 |

109 - 170 |

190 - 320 |

190 - 320 |

275 - 410 |

| Max Operating Pressure |

BAR |

350 |

350 |

350 |

350 |

350 |

350 |

| Rotational Speed |

RPM |

90 - 160 |

80 - 135 |

60 - 110 |

60 - 90 |

50 - 90 |

55 - 85 |

| Max rock hardness |

MPA |

25 |

40 |

50 |

70 |

80 |

100 |

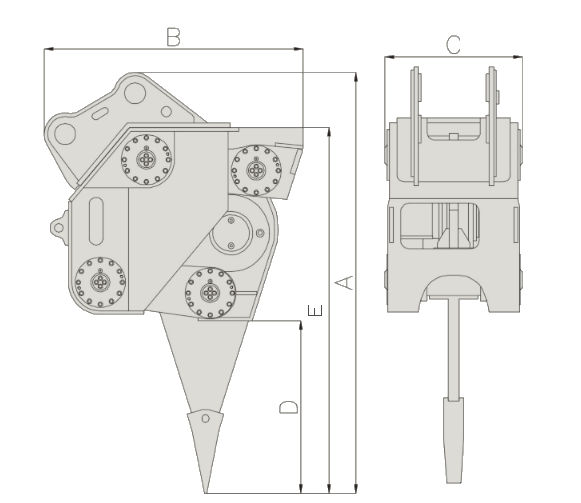

| Length of Rock Grinder |

A |

740 |

740 |

990 |

1,200 |

1,200 |

1,300 |

| Width of Grinder Head |

B |

615 |

660 |

730 |

880 |

920 |

950 |

| Diameter of Ginder Head |

C |

370 |

370 |

560 |

670 |

670 |

710 |

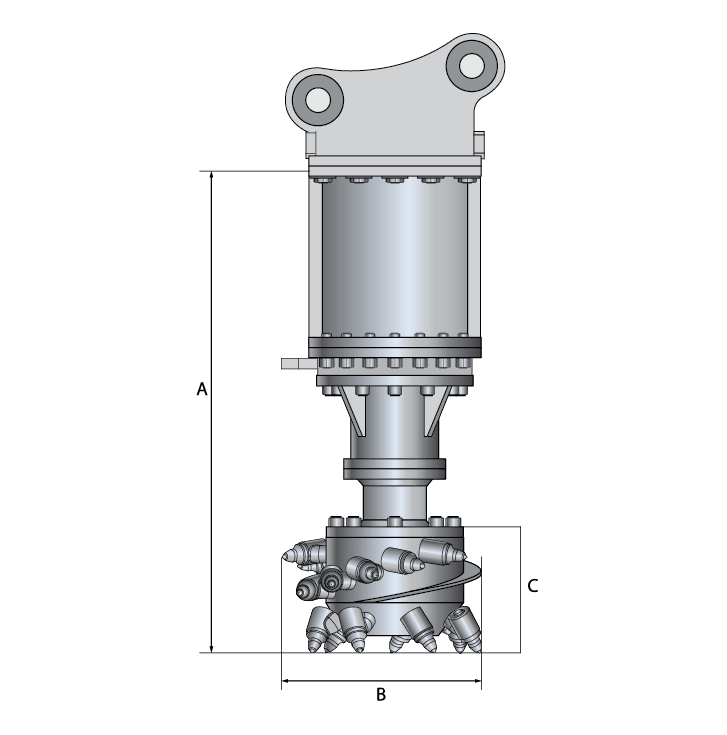

RGL Single Head Rock Grinder

| Standard Specification |

| Technical Data |

Unit |

RG20L |

RG30L |

RG40L |

| Carrier weight class |

TON |

15 - 23 |

20 - 30 |

25 - 35 |

| Service Weight |

KG |

820 |

1,200 |

1,200 |

| Oil Flow Rate |

L/MIN |

140 - 250 |

180 - 300 |

180 - 300 |

| Max Operating Pressure |

BAR |

350 |

350 |

350 |

| Rotational Speed |

RPM |

60 - 90 |

60 - 90 |

50 - 90 |

| Max rock hardness |

MPA |

60 |

70 |

80 |

| Length of Rock Grinder |

A |

990 |

1,200 |

1,200 |

| Width of Grinder Head |

B |

750 |

880 |

920 |

| Diameter of Ginder Head |

C |

560 |

670 |

670 |